If you have even a passing interest in raw denim, you’ve probably heard the word Selvedge more than a few times. No, it doesn’t refer to someone who vends lettuce, the word selvedge refers to the way a textile has been woven.

You can usually spot selvedge denim by the tell-tale colored lines that often run along the outseam of a pair of jeans, but what exactly does that mean?

What is Selvedge Denim?

Selvedge outseam on a pair of Companion Denim jeans.

Selvedge goes by many spellings (selvage, self-edge, and selvedge) but it all equates to the same thing — the self-binding edge of a fabric woven on a shuttle loom. That definition may sound a bit jargony, but trust us, all will soon make sense.

It’s important to note that selvedge denim is not the same as raw denim. Selvedge refers to how the fabric has been woven, whereas raw refers to the wash (or lack thereof) on the fabric itself.

How to Recognize Selvedge Denim

Non-selvedge denim produced by projectile looms has an open and frayed edge denim because all the individual weft yarns are disconnected on both sides. To make jeans from this type of denim, the edges have to be overlocked to keep the fabric from unravelling:

An example of overlocked non-selvedge denim.

Selvedge denim is woven in a way that leaves the length of woven fabric with a clean edge on both sides (we’ll cover this next). This clean edge appears on the outseam of a pair of jeans. So, to check for selvedge denim, just roll up the cuff and check the outseam for a bold white edge that is typically filled with a colored thread running through it, like so:

The selvedge ID on a pair of Full Count x Blue in Green 1101SR Jeans via Blue in Green.

How is Selvedge Denim Made?

Vintage Shuttle Loom

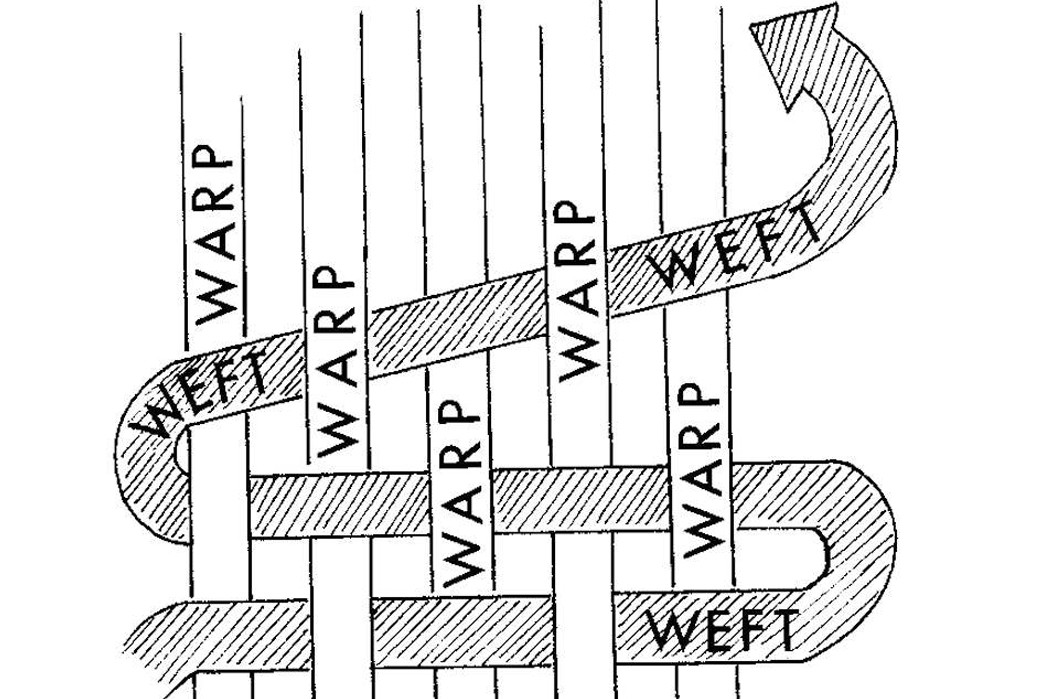

To understand how manufacturers make selvedge denim, we first have to understand a little bit about textile manufacturing in general. Almost all woven fabrics are composed of two parts with two parts: warp yarns (the ones that run up and down) and weft yarns (the ones that run side to side).

To weave a fabric, the loom holds the warp yarns in place while the weft yarn passes between them. The difference between selvedge and non-selvedge fabrics is all a matter of how that weft yarn is placed into the fabric.

A shuttle full of weft yarn.

Up until the 1950s, almost all denim was produced on Shuttle Looms. A shuttle loom is a weaving textile loom which uses a small device called a shuttle to fill in the weft yarns by passing back and forth between both sides of the loom. This leaves one continuous yarn at all the edges so the fabric self-seals without any stray yarns.

How warp and weft fabrics intertwine on a shuttle loom.

Slow, Steady, and Narrow

Most shuttle looms create a textile that is about 36 inches across. This size is just about perfect for placing those selvedge seams at the outside edges of a pattern for a pair of jeans. This placement isn’t just aesthetically pleasing, but practical as well as it saves whoever’s sewing the jeans a couple extra passes on the overlock machine and ensures the jeans will not fray at the outseam. The image below exhibits this.

An example of how the quarters of a pair of jeans conveniently line up along the selvedge of shuttle woven denim.

The demand for more denim after WWII, however, soon forced mills to adopt mass-production technology. A shuttle loom can place about 150 weft yarns per minute on a 36-inch wide textile. A Projectile Loom, however, can place over 1000 weft yarns per minute on a textile that’s twice as wide, thus producing nearly 15 times more fabric in the same time span.

A modern projectile loom, note the much wider textile.

The projectile loom achieves its speed by firing individual (and unconnected) weft yarns across the warp. This is a much more efficient way to weave fabric, but what’s lost is that cleanly sealed edge (the selvedge).

Why is Selvedge Denim So Expensive?

Selvedge denim is expensive because it is more time-consuming to make. As explained in the prior section of this article, selvedge denim is woven on shuttle looms that weave less denim than modern projectile looms and at a slower rate. They also require a skilled person with knowledge of the machine to operate. That’s the crux of selvedge denim’s expense, but the cost of the final product is also impacted by numerous other factors.

It’s important to note that many brands making selvedge denim goods will be taking a more nuanced and artisanal approach throughout the whole process of garment manufacturing – choosing special cotton fibers for the denim, dyeing those yarns in small batches with specific dyeing techniques, and finally, of course, constructing a high-quality garment.

Selvedge denim is often partnered with vintage construction techniques to create classic-looking products. Details like chain stitching, custom leather waist patches and hardware, raised belt loops, and more, require expertise that also contributes to cost. Sure, a big brand like Uniqlo can sew up some selvedge denim jeans and charge less than $100 for them, but they won’t have the same level of detailing as a pair from, say, Samurai Jeans or Tellason, and they won’t be made by denim artisans in Japan or skilled garment makers in America.

Why is Selvedge Denim So Popular Today?

Jelado washed selvedge denim via HINOYA.

The resurgence of selvedge denim is nothing short of remarkable. The comeback was pioneered by Big John and the Osaka 5, when brands like Warehouse & Co., Full Count, and Evisu began meticulously reproducing classic workwear styles from the early-to-mid 20th century – most notably raw selvedge denim jeans and jackets. Many of these brands went as far as to pick apart and micro-examine original selvedge articles from the big 3 — Levi’s, Lee, and Wrangler — in order to understand what made old American selvedge denim so good.

While Levi’s has stayed producing raw selvedge denim 501 jeans (Levi’s 501 STF), it was the selvedge denim coming out of Japan that began to captivate menswear aficionados and streetwear heads looking for the best jeans on the market back in the 90s. The attention to detail deployed by the aforementioned Japanese brands and their peers was impossible to ignore and once Japanese selvedge denim had fully caught on in the West, it set a benchmark that had Western brands scrambling to offer comparable denim garb.

The Japanese had taken an American icon and arguably bettered it, weaving selvedge denim on old Toyoda shuttle looms and sewing it up into top-class five-pocket jeans, trucker jackets, and more. But the USA responded with its legion of its own makers, who used the country’s bedrock of selvedge denim production to bring American denim into the modern day. Brands like Raleigh Denim, Jean Shop, and Tellason all contributed towards the growing selvedge denim scene in the USA, with major players like Levi’s (notably through its Levi’s Japan label) and Ralph Lauren (Under the RRL label) increasing their selvedge denim output massively.

Once both sides of the hemisphere were in full swing, selvege denim became an infectious niche with numerous forums, a popping subreddit, and a host of boutique stores across the globe selling Japanese, American, and even European selvedge denim goods.

The selvedge detail on the upturned cuff quickly became one of the “things to have” among those passionate about quality goods.

Where is Selvedge Denim Made?

The overwhelming majority of denim fabrics made today are open-end and non-selvedge. There are only a handful of mills left in the world that still take the time and effort to produce selvedge denim.

Those colored lines on the outside edge are called Selvedge ‘IDs’ as they used to indicate which mill produced the denim. Cone Mills (RIP) in North Carolina had a red ID, whereas Amoskeag Mills up in New Hampshire had a green ID. Nowadays, most selvedge ids are used purely for decorative and ornamental purposes, but a few of the old mills live on.

A variety of selvedge ids. Image via Taylor Tailor.

The most well-known selvedge denim mill was Cone Mills which produced denim out of their White Oak Plant in Greensboro, North Carolina, from the early 1900s to the late 2010s. Before closing, they were the last selvedge denim manufacturer left in the United States. Other noteworthy mills include Kuroki, Nihon Menpu, Collect, Kaihara, Kurabo, Nisshinbo, and Toyoshima —all of which are in Japan —Candiani and Blue Selvedge in Italy. Almost all of the artisanal denim brands will specify which mill their denim is coming from, so look for the names listed above.

The increased demand for selvedge denim has prompted many mills in China, India, Turkey, and elsewhere to produce it as well. While selvedge fabrics from these countries aren’t all bad, they will typically use lower-grade cotton and cheaper dyeing techniques. If in doubt, it’s best to go for a smaller denim brand that lists the mill used, or at least has an ironclad reputation for quality.

Where to Buy Selvedge Denim

The boom of selvedge denim means you can find selvedge denim from big companies like Gap, Uniqlo, and J.Crew. If you’re in a major city, though, chances are you’re not too far away from speciality denim stores that can show you a wide variety of options from the top makers in the scene. Thanks to the internet, you’re never more than a couple of clicks away from some of the finest jeans ever produced.

There are hundreds of brands making selvedge denim goods, but here are a few picks from some of the best in the world. Be sure to keep up with our New Releases feed for more selvedge denim goods from more amazing brands.

Jeans

Warehouse & Co.

Warehouse & Co. S100XX ‘Deadstock Blue’, available for $325 from Clutch Cafe.

Full Count

Full Count 0105 Loose Straight (left) and 1108 ‘New Straight’, both available from Clutch Cafe for $315.

Burgus Plus

Burgus Plus Lot.771 15 oz., available for $155 from Hinoya.

Pherrow’s

Pherrow’s 451 13.5 oz. Jean, available for $215 from Clutch Cafe.

Momotaro

Momotaro Lot.0105SP 15.7 oz. Extra Dark Indigo Jeans, available for $235 from Hinoya.

Ginew

Ginew Crow Wing 14 oz. Made in USA Straight Leg Jeans, available for $283 from Ginew.

Tellason

Tellason Ladbroke Grove Slim Tapered Jeans, available for $240 from Tellason.

Samurai Jeans

Samurai S710XX19II 19 oz. Kiwami Selvedge Denim Jeans, available for $335 from Franklin & Poe.

Jackets

Sugar Cane

Sugar Cane 1953 Type II selvedge denim jacket, available for $225 from Franklin & Poe.

The Strike Gold

The Strike Gold SGJ50S 15 oz. Slub Grey Weft Denim Jacket, available for $273 from Redcast Heritage.

Iron Heart

Iron Hear Un-Modified Type III 21 oz. Raw Selvedge Denim Jacket, available for $435 from Iron Shop Provisions.

The Flat Head

The Flat Head 10 oz. Selvedge Denim Coverall, available for $285 from Corlection.

Now that you’ve read all about selvedge, have you also read our comprehensive Guide to Raw Denim?